Introduce

Mining is a highly specific industry relying greatly on large equipment for its operations. Despite being rather distinctive and dealing with issues that other industries do not have to, mining companies can manage their daily activities seamlessly thanks to technology. Dashcams and GPS tracking devices will help meet the challenges that the mining industry is facing today and, at the same time, will prevent unwanted expenses and complications.

Challenge

In the mining industry, there are many challenges at all stages of the business cycle.

The costs of heavy machinery are enormous, and it is estimated that its’ average productivity is only 62% at best. That means that this expensive equipment is not being used for a lot of time. It is unacceptable that such costly machinery is so barely used and results in higher costs than it could be.

Furthermore, spending time idling is another big challenge. It is estimated that, for example, one manufacturer’s heavy machinery is idling 40 percent of total running time, resulting in 400 gallons in annual fuel waste per machine. These actions create very high costs, especially in larger fleets, that could be prevented with the help of smart telematics solutions. It is necessary to prevent situations when valuable materials are unloaded out of a dump truck without authorization, especially in times of rising construction prices, harsh competition, and construction materials being among top cargo theft targets.

Moreover, it is also difficult to ensure that the driver of heavy machinery does not work in certain unsafe areas. If a driver accidentally starts to work outside the authorized area, he/she must be informed and stopped immediately.

In addition, transportation tools are needed to move heavy equipment and transport mineral products. However, mining areas are usually located in remote areas, and data transmission will be delayed or even lost, resulting in assets that cannot be tracked and monitored in real time, or even lost.

Solution

When you’re managing a fleet of vehicles and heavy equipment in construction, you have to know where everything is and what it’s doing at all times. Jimi provides heavy equipment monitoring solutions, providing an all-encompassing solution for vehicles, drivers and assets.

Dashcam technology has evolved into a sophisticated mobile vehicle DVR (Digital Video Recorder) system with front and rear dashcams embedded with multiple smart sensors and 4G connectivity to provide cloud-based real-time vehicle tracking, monitoring and alerts.

Integrating artificial intelligence (AI) adds an important dimension to the fleet, providing not only details of events but complete context. Dashcams can now recognize when a driver’s eyes are no longer focused on the road and send an automatic alert both in the car and to the operator in the field.

With the automatic upload of video footage to the cloud and easy scalability, today’s dashcam systems are everything fleet operators in the construction and mining industries have been waiting for.

In addition to the physical monitoring aspect of the solution, there is also a GPS tracker. Fleet managers can gain real-time visibility into where vehicles are located, including how they are being driven.

How it Works

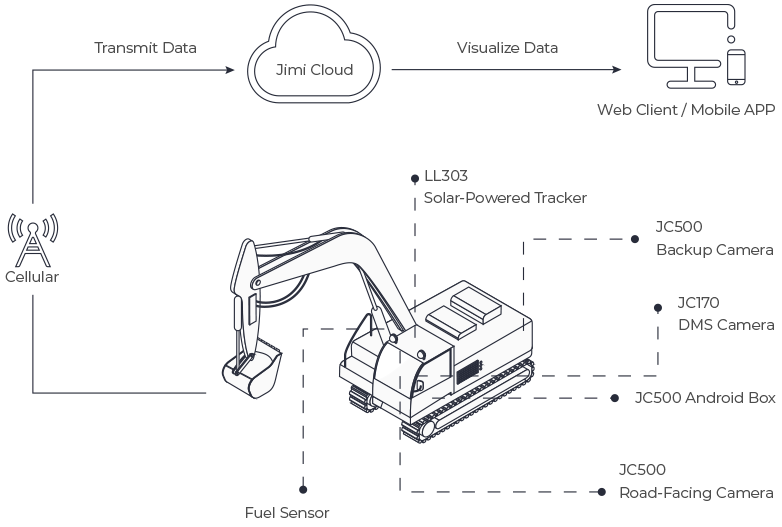

DEVICE

Jimi trackers and dashcams installed on the equipment collect data about statuses including idling, monitor driver and road conditions, assist in reversing, and remind drivers with actionable in-cab alerts if any exception occurs. With peripheral support, our devices can be customized to suit most construction applications. In addition, the tracker is handy in case of an emergency. A single press of the SOS button will alert you that your field staff needs assistance, giving you peace of mind.

CLOUD

As the data from your devices is analyzed by the cloud server, the most important data from your business is visualized in intuitive graphs and lists on a platform or mobile app (Tracksolid Pro or your own) so that operators or managers can see the field situation intuitively in real-time from the back office.

PLATFORM

The platform alerts operators or managers if any exception occurs, such as fuel theft, driver fatigue, or leaving or entering a geofence. In addition, you can track traveled routes, monitor drivers and heavy machinery in real-time, plan routes, schedule maintenance, and track fleet distribution. By doing so, you will be able to have better control over the field fleets and mobile workforce.

Benefits

In the mining industry where a large number of products are constantly in circulation, whether it is machinery or fleets, the key to effective planning, real-time monitoring, accurate data, and organization of daily operations is continuous and no-delay access to information, which is critical to delivering goods on time, providing efficiency, Reducing theft is critical. Fortunately, the combination of Jimi’s dashcam and GPS tracker provides the perfect solution for the mining industry.

Cable-Free Network Connectivity

All Jimi devices are equipped with an internal network module. It saves the time and hassle to route network cables for monitoring devices in the already-complicated construction site, making this solution a suitable choice for projects that are small or need temporary work. This further shortens the time to move in and move-out and lowers the cost of technical maintenance.

Preventive Maintenance

Studies suggest that preventive maintenance can save an average of 12% to 18% in costs. Preventive maintenance can be a game-changer. It enables heavy equipment fleet managers or operators to act proactively instead of reactively by scheduling regular maintenance. This reduces the cost of unplanned downtime and ensures uptime to guarantee projects are completed on time and protect your good reputation.

Programmable Geo-Fence

By pre-drawing geofences on the cloud-based platform, you can see the distribution of your equipment assets, determine if they have reached the predetermined sites, and know clearly what types of machinery and equipment are in the yard for dispatch and which are nearest to the required job site.

Track and Trace

Live GPS to pinpoint equipment fleet stolen, onroad, and in the yard and travel history including distance, time, and speed to see if your construction equipment fleet has been detoured or gone to non-work sites for private use.

Real-TimeVideo Insight

The Jimi camera system allows managers or operators to remotely monitor their field drivers’ attentiveness like fatigue or distraction (DMS) and helps monitor the blindspots of the construction vehicles and the rear of the equipment fleet to assist in reversing or parking.

ActionableAlerts

The platform allows managers or operators to decide which events are important to them and set separate alerts, so they are only notified of matters of the greatest significance and take action at the right moment to maximize productivity, utilization, and profitability.

Why Jimi IoT

As well as improving efficiency and cost reduction benefits, Jimi dashcam mining solutions are also useful from a monitoring and alerting point of view. Because these dashcam solutions are able to recognize when drivers are distracted, site managers can use this capability to ensure drivers keep their eyes on the road and focus on the task at hand.

Also, safety means focusing on the driver, not just the vehicle. For example, when operating a mining drilling vehicle, construction excavator, etc., it is useful to be able to visually determine what the driver was doing at the time of the accident to determine a fault.

With 20+ years in the business, 40+ products and solutions, 300+ R&D professionals, 150+ countries and territories, 1,000+ partners and high-quality tracking hardware, and easy-to-use cloud platform, Jimi is trusted by businesses and consumers worldwide. With the help of Jimi hardware and software, our customers are able to achieve lower costs, higher productivity, and safer driving.

EN

EN ES

ES PT

PT TH

TH VN

VN JP

JP