Introduce

According to Fortune Business lnsights, the global market size of cold chain logistics in 2020 is 221.85 billion US dollars, and it is expected to reach 647.47 billion US dollars by 2028.

Rising number of retail chains such as organized convenience stores, hypermarkets, and supermarkets across the globe and rising consumer demand for perishable goods are driving the growth of the cold chain logistics market. Moreover, in the pharmaceutical industry, the COVID-19 pandemic (mainly vaccines) has had a positive impact on the cold chain industry, thereby driving the global demand for cold chain transportation and refrigerated storage.

The cold chain transportation segment is expected to grow at the fastest CAGR during the forecast period owing to the increasing use of safe cold chain transportation of temperature-sensitive goods and products. The transportation methods used are refrigerated goods, refrigerated rail cars, refrigerated trucks and air freight.

In the next few years, infrastructure upgrades such as fixed refrigerated warehousing, portable refrigerated storage and refrigerated trucks will bring more opportunities for cold chain transportation.

Challenge

Challenges always coexist with opportunities. In the cold chain transportation industry, there are four main challenges as follows.

1. Cost

Last mile cold chain for groceries is a complex and costly business model. Retailers need to pivot some of their strategies to provide excellent customer experiences while keeping logistics processes as efficient as possible.

2. Temperature Control

Cold chain logistics requires highly specialized temperature-controlled equipment and facilities to maintain the required temperature range during transportation, warehousing, and distribution. Any breakdown or malfunction of the cold chain system could result in food spoilage or other degradation.

3. Technology

Technology plays a critical role in cold chain logistics to monitor and control temperature and humidity levels, track product location, and ensure proper handling throughout the supply chain. The high cost of technology and skilled personnel needed to operate and maintain the systems significant pose a challenge .

4. Government Regulations

The foods and pharmaceuticals transported in the cold chain are highly sensitive products. Hence they are subject to rigorous regulation by government agencies to ensure the safety and quality of the products. cold chain logistics and temperature-controlled transportation to protect the effectiveness of vaccines. However, maintaining the cold chain throughout global transportation networks can be challenging due to logistical complexities that pose a risk to the efficacy of the vaccines.

Although enterprises have strict requirements on cold chain logistics, there are still many safety hazards in the complicated and changeable cold chain transportation process. For example, there is no temperature and humidity monitoring in the refrigerated compartment, the company cannot supervise the transportation route, there is no early warning mechanism for the transportation process, and it is impossible to trace the source and pursue responsibility.

Solution

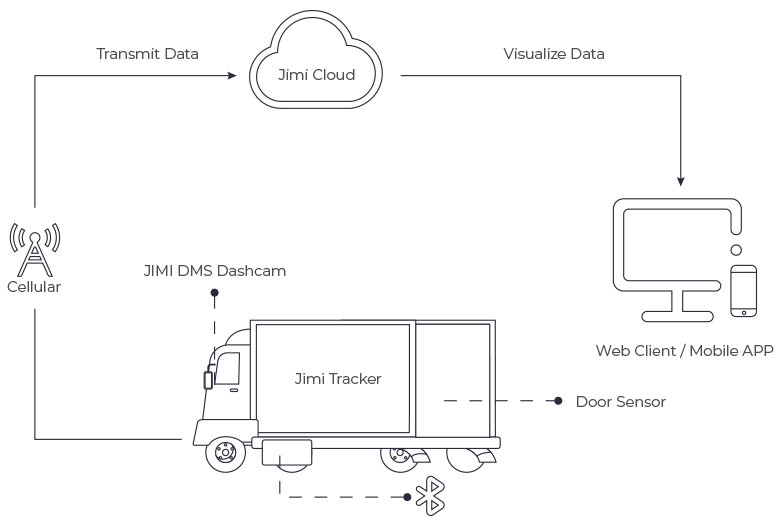

Aiming at the problems in the cold chain logistics process, Jimi &Concox uses LL301 LTE Cat 1 asset GNSS tracker to launch a cold chain logistics asset tracking and monitoring solution.

DEVICE

Jimi &Concox dashcams, trackers, door sensors, and fuel level sensors installed in the cabins and cold chambers of the reefer trucks and trailers collect critical data in real-time about location, door status, temperature and humidity, drivers and their driving behavior, and more , and upload the data using the cellular network to the cloud server.

CLOUD

The cloud server analyzes the data and visualizes them in intuitive graphs and lists on the designated web client or mobile app, so managers can have a clear understanding of the current statuses of their fleets, cargoes, and drivers.

PLATFORM

The platform alerts managers or drivers if any exception occurs such as fluctuating temperature or humidity, fatigue or distracted driving, harsh acceleration, hard braking, harsh cornering, low fuel level, and the door left open for too long, so they can act accordingly.

Benefits

LL301 GPS asset tracker can achieve super long standby time with 10,000mAh high-capacity battery and durable casing. The device has multiple positioning systems and indoor and outdoor signal coverage. Communicates over 4G LTE networks with 2G GSM fallback instant alerts of atypical events like device removal, vibration, etc. We also provide users with remote monitoring targets through our cloud platform and mobile application.

And with near-zero installation, the LL301 attaches easily and securely to most metal surfaces. The device can be configured quickly and easily via the app for iOS.

Uninterrupted Monitoring

Cold chambers and refrigerated vehicles are monitored 24/7/365 and the auto data logging saves manpower and time and the readings are much more accurate. And the data can be viewed in real-time on any internet-connected device from anywhere.

ActionableData

The platform allows managers to decide which events are important to them and set separate alerts, so they are only notified of matters of the greatest significance and take action at the right moment to reduce spoilage and mitigate losses caused by outdated information.

Real-time Location Tracking

With GNSS. WiFi, or cellular networks, managers can always know the whereabouts of their refrigerated fleets. This helps reduce inquiries from customers (as you can always show them where the cargoes are with screenshots or images) and streamline deliveries

Programmable Geo-fence

By preset geofences via the platform, cold chain managers can get real-time notifications about when and at which warehouse reefer containers arrive during transit, as well as when they will arrive at their destinations. This can protect your good reputation.

Regulatory Compliance

Using the platform, managers can configure the device to take temperature and humidity readings in cold chain transport vehicles at intervals specified in food safety regulations. Ensuring compliance throughout the entire delivery process.

Seamless Integration over API

Jimi IoT offers an API protocol to integrate our devices with your transportation management system (TMS) and enable you to access all the data collected by Tracksolid Pro at various stages of the cold chain.

Why Jimi &Concox?

Together with LL301 GPS tracker, combined with Jimi &Concox driving recorder, door sensor and fuel oil level sensor and other equipment, the temperature and humidity, location, door opening and closing status and other information are sent to the monitoring platform through the 4G network, and the delivery time, delivery route and temperature changes are monitored. Carry out whole-process management to reduce the impact on the quality of goods caused by temperature changes. This solution ensures that the storage environment and temperature of refrigerated goods are stable in each link of transportation, and realizes real-time monitoring of the logistics status of cold chain goods.

With 20+ years in the business, 40+ products and solutions, 300+ R&D professionals, 150+ countries and territories, 1,000+ partners and high-quality tracking hardware, and easy-to-use cloud platform, Jimi &Concox is trusted by businesses and consumers worldwide. With the help of Jimi IoT hardware and software, our customers are able to achieve lower costs, higher productivity, and safer driving.

EN

EN ES

ES PT

PT TH

TH VN

VN JP

JP